Customer Spotlight: Gold Plating a Crown from the Philippines

Written by Annabelle

October 31, 2019

When it comes to our gold plating service, we receive a lot of jewelry…and some less common items. To date, we've gold plated an unidentifiable piece of stainless steel, a pair of glasses, a swimming championship medallion, and even brass caps for an antique rifle enthusiast.

But when our customer Roger messaged us about a crown- well, that was definitely new territory. Read on to learn how we performed a full restoration on this hefty piece.

Customer's Piece: A Five-Inch Wide Crown

When Roger reached out to us, he asked us if we had the capability to plate a crown that he had purchased in the Philippines. We were intrigued and asked for images. Roger provided us with a few photos of the crown next to a ruler, allowing us to see its approximate dimensions.

Roger's pictures of the crown next to a ruler.

The crown measured roughly at 5 inches wide, and 4 and a half inches tall. After some consultation with our plating specialists, we determined that it would fit inside our gold plating tank, so we got back to Roger and told him to send it over.

The Gold Plating Process

Typically, the gold electroplating process involves a good polishing, cleaning, and submersion of the item into a gold plating tank. The tank is filled with a solution containing gold metal salts and water. Electricity runs through the tank, causing a chemical reaction that bonds the gold to the surface of the item.

While this method works well for standard metals such as sterling silver and white gold, Roger's crown posed a bit of an issue. When we received the crown, we immediately noticed that it was still covered in a gold, flaking coat. At that time, the metal was unidentifiable.

The crown was originally covered in what appeared to be paint or flaking gold plate.

Working carefully, we polished a little bit on the interior of the crown to see if we could determine the nature of the metal. The small spot that we worked on revealed itself to be shiny and gray-white in color. We were stumped for a moment- it wasn't sterling silver, but some type of unknown metal or alloy.

This complicated matters, because certain metals require special treatment to take to the gold electroplating process. Some metals are just not conducive at all to the process and will not even take the plating. In order to see if the crown could be plated, we had to entirely remove the existing gold coloration and test it in our plating tank.

After some discussion with Roger, we decided to proceed and do just that. The crown was heavily polished, stripping it of its existing coat and revealing the gray material underneath. In order to avoid any unnecessary contamination of the plating tank, we also unset the original stones in the crown so that the glue in the settings could be removed. At this point, our plating specialists were able to determine that the mystery metal was in fact carbon steel.

As a preventative measure and to increase the chances of the gold plating adhering to the crown, our plating specialists decided to copper plate and nickel plate it. These preliminary plating procedures helped to chemically prepare the piece for the gold plating process.

The crown freshly out of gold plating.

After a few days of work, we successfully got the gold plating to adhere onto the metal! The crown came out of the tank and our office was in awe at how glossy and bright it looked in comparison to its original appearance. However, we were not finished: Roger had also mentioned that he wanted to replace the stones as well.

Stone Sourcing

Stone replacement for this piece was a little tricky. As the settings of the crown were not genuine functioning settings- that is, they could not actually hold the stone- we would not be able to set gemstones into the piece the traditional way. Fortunately, Roger had mentioned his interest in Swarovski crystals, which come in a flatback style. This meant that the crystals had a foil backing for extra sparkle, allowing us to fix the stones onto the crown with jeweler's epoxy.

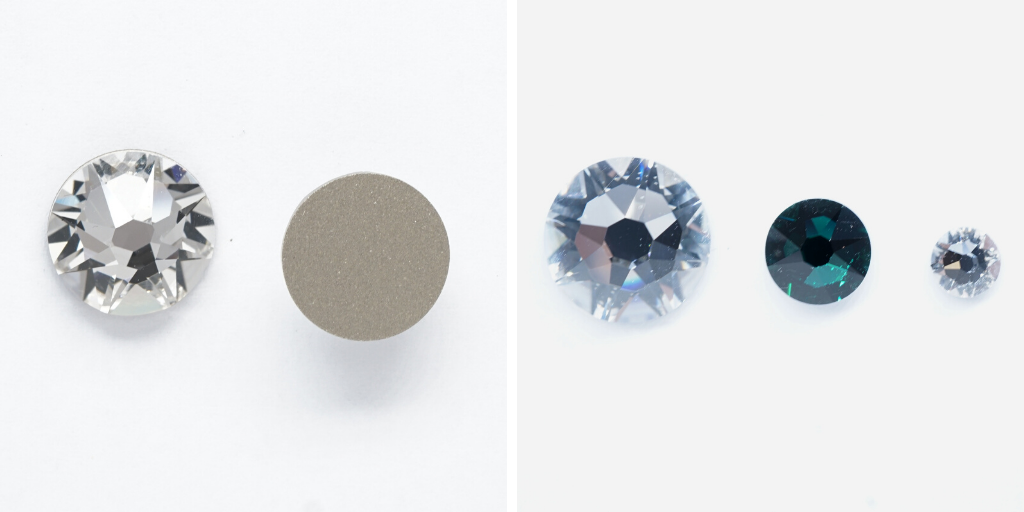

The next step was to find crystals in the right size for Roger's crown. There were three different sizes of crystals we had to source: one for the very top point, six medium-sized ones for the side panels, and six large ones for the circles around the rim. Roger also informed us that he wanted clear/white crystals for the 12 stones on the crown, and an emerald one for the top point.

With the help of our lapidary we were able to procure all of the crystals. The last size was difficult to find because extremely large Swarovski crystals are not commonly used, but we managed to source some with a similar diameter.

The crystals, front and back. Note the compass rose cut.

The Finished Piece

The crown, before and after!

Once the stones were set, the crown was finished! With its new smooth gold aesthetic, complete with glittering Swarovski crystals, the crown was ready to ship. We texted Roger and ensured that the gold plated crown would be delivered in time for his wife to wear with her Halloween costume.

When it comes to unusual and interesting things we've worked on, this crown is definitely in the top ranks! If you have something similar you'd like us to work on, comment below or contact us directly.

We have an old, maybe 10 inch metal statue of our Blessed Mother whose previous gold plating gas worn off with handling and time. Can you replate it? At how much time and cost ? Thanks.

Hi Toby, I’m not sure if this would be something we can plate! We’ll email you with further details

Sane question here. Can you plate a Marian crown?

Hi Jeanette, thank you so much for your comment! We’d love to help you with your Marian Crown. I reached out via email to help you with the next steps